Stay informed of the latest news and specials.

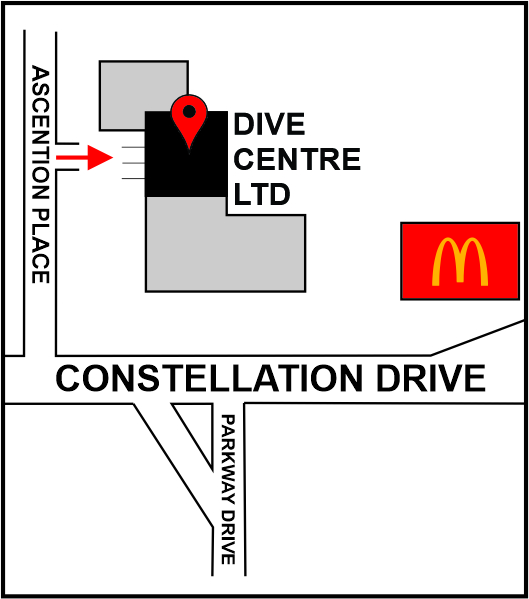

1 Ascension Place, Rosedale, Auckland 0632

Deliveries to: 5/20 Constellation Drive,

Rosedale,

North Shore,

Auckland 0632

Ph: +64 9 444 7698

We have finished our two brand new "State of the Art" service bays with two matching sets of the most advanced service equipment available in the world!

Imported from specialist manufacturers overseas, these machines, bench equipment, and tools are cutting edge and designed to ensure that your equipment is maintained to the highest global standards.

We now have two fulltime service techs, using their decades of experience and the best service equipment available, to make sure you have fun safely underwater this season and many to come!

We have imported regulator testing equipment that no one else has in New Zealand.

In this new "post-covid" world, we have upgraded our diagnostic and tuning bench equipment to eliminate the need for a service tech to ever breathe through your regulator, and even vacuum tests 2nd stages to ensure they are watertight! A design that provides piece of mind to you and us, and is a first for New Zealand!

We even have a machine that "beds-in" the new high and medium pressure seats in your reg before we tune it. This means no freeflow issues during your first dives after servicing - just another way we are using new technology and upgraded procedures to ensure you don't have gear issues in the water.

In an equipment intensive sport such as this, it is important to have your gear routinely inspected. Small equipment failures can result in large problems! At Dive Centre we specialise in Certified Repair for all brands. We are a wholesale repair facility - that means we not only service our customers equipment - but provide this service for other stores all over New Zealand as well; using two of the most experienced, fully qualified and highly trained technicians in New Zealand.

By investing in our facilities and staff, and by making the commitment to do all aspects of equipment maintainence, testing and repairing on-site, we control every stage of the process, so we can ensure only the latest equipment and techniques are used to maintain your scuba equipment.

Don't let a malfunction leave you high and dry on your next dive trip. Let us maintain your equpiment properly, so you can get in the water every time!

We also have the most advanced Dive Computer Battery Change and Service Facilities in New Zealand! We service all brands of dive computer including Suunto Watch repairs and battery changes as well as Big Display Suunto battery changes.

We also do battery changes and repairs on mechanical dive watches.

With the release of AS/NZS2299.1:2015 there are now requirements for Occupational Divers in regards to air pressure and depth gauge accuracy testing and regulator hose testing.

We are now able to offer full testing of SPG's, Mechanical Depth Gauges, Computers and hoses to this new standard.

All Occupational/Commercial divers are required by this standard to have the accuracy of these items tested at least every 12 months or in the case of heavy or rough use every six months.

Please contact Malcolm Kidd on 094447698 for more details.

Not all Air fill stations are built the same! With Dive Centre Air, you are guaranteed to have air that far exceeds New Zealand and International Standards. For those of you in the know, we deliver "Grade E" air quality. Not many other Air Fill facilities in New Zealand can make this statement.

Not all Air fill stations are built the same! With Dive Centre Air, you are guaranteed to have air that far exceeds New Zealand and International Standards. For those of you in the know, we deliver "Grade E" air quality. Not many other Air Fill facilities in New Zealand can make this statement.

How do we achieve this exceptionally clean air? Again by investing in the best! We installed a brand new Bauer Verticus 5 V180-15-5 Super Silent compressor. This compressor is computer controlled and even samples the air and will automatically shut down if air quality exceeds NZ standards! Now that's piece of mind for you and us. We have our Air tested every three months for Air Quality ensuring that our system is giving you the cleanest air possible. As of December 2015 a new standard AS/NZS 2299.1:2015 came in which reduced the amount of moisture allowable in scuba breathing air. You'll be happy to know that we are well below this new standard without having to do anything to our system! Being serious about air quality, we also only use the experts at High Pressure Equipment, to service our air quality systems.

We also have massive storage banks that can be used to fill up to 15-20 cylinders without starting up our compressor. This means we can fill while-you-wait 7 days per week, no matter what! We do this by utilising a "Haskel Pump". This expensive piece of equipment is an air driven pump that uses air from storage to pump the air into your cylinder. This allows us to fill cylinders even during a power cut!

Ultimate convienience and reliability for you when you are in a hurry to get out on the water.

Imagine all the benefits of diving Enriched Air, without any of the hassles of dedicated cylinders or O2 cleaning!

A lot of people diving Enriched Air use it to dive safer, not as a technical dive as most people think!

How does Enricher Air (Nitrox) benefit a typical kiwi diver like yourself? If you do a dive to 18 metres, and spend 50 minutes of the 56 minute maximum, you are fairly close to the limits. But if you use 40% Enriched Air and do the same dive, you will have used only 50 minutes of a 125 minute maximum! Other benefits of Enriched Air, are that you can spend longer at depth than on air, or minimise surface intervals and you feel much less tired after a day's diving.

Usually cylinders have to be specially cleaned for Enriched Air, but thanks to Dive Centres new advanced "De-Nitrogenated Air Nitrox" filling system this is no longer required! Just a simple inspection, some new stickers and your cylinders are ready. Your Regulator, BCD, and the rest of your equipment does not have to be specially cleaned or altered!

Usually cylinders have to be specially cleaned for Enriched Air, but thanks to Dive Centres new advanced "De-Nitrogenated Air Nitrox" filling system this is no longer required! Just a simple inspection, some new stickers and your cylinders are ready. Your Regulator, BCD, and the rest of your equipment does not have to be specially cleaned or altered!

We have a Bauer K14 10 cfm (cubic foot per minute) compressor that is not only a back up to our main compressor but runs our Dnax Membrane Enriched Air fill Station as well.

We take the already Super-Clean air from our storage, and feed this through three more filters before it goes into your cylinder via the Membrane! (This is very clean air!)

A Membrane is basically a type of filter, its real name is a Permeable Membrane which means it separates the Nitrogen and Oxygen, at a molecular level, from our storage air. All we have to do is turn a dial, and it separates more Nitrogen off, so we end up with a higher level of Oxygen going to our Enriched Air Compressor. Because the Enriched Air is going into the compressor and cylinder at 40% or below, the cylinders don't have to be O2 clean. This is far more convienient for you, because it means you can choose to dive on Enriched Air one day, and normal Air the next, no dedicated cylinders! Unlike older systems that put 100% Oxygen into the cylinder and "Top-up" with normal air, to hopefully end up at the % you wish.

We test cylinders in-house!

We test cylinders in-house!

We do not have to send cylinders out to have them tested like other smaller stores on the North Shore. This means faster turn around times and you can talk to the certified experts if you have any questions!

But again, not all cylinder test stations are the same either!

We are an IANZ Cylinder Testing Laboratory adhering to ISO 9002 standards, which is the most advanced cylinder testing system in New Zealand. We are authorised to test Scuba and BA cylinders, Domestic LPG Cylinders, Primus LPG Cylinders, Industrial Gas Cylinders, Automotive LPG Cylinders & Automotive CNG Cylinders and even large Air Storage Cylinders for other dive stores as well! We are certified to test up to 800 Bar test pressure cylinders!

Scuba Cylinders require testing every single year. A visual inspection in the first year, and a Hydrostatic Test the following year. And the test alternates each year after that. If it's been more than 2 years since any test was performed; it just has to be Hydrostatically tested.

LPG Cylinders are required to be tested every 10 years.

Don't throw away your perfectly good cylinder and buy a new one. Save money and the environment - Go Green & Recycle - Test your LPG cylinder instead.

Automotive LPG Cylinders are tested every 10 years like their smaller domestic counterparts.

Automotive CNG Cylinders are tested every 5 years.

It doesn't matter if your Scuba cylinders just need their yearly test, your LPG Cylinder needs its 10 year test, or even just a valve repair, we are the cylinder experts!